A New Zero-Waste Process Technology

Our Process

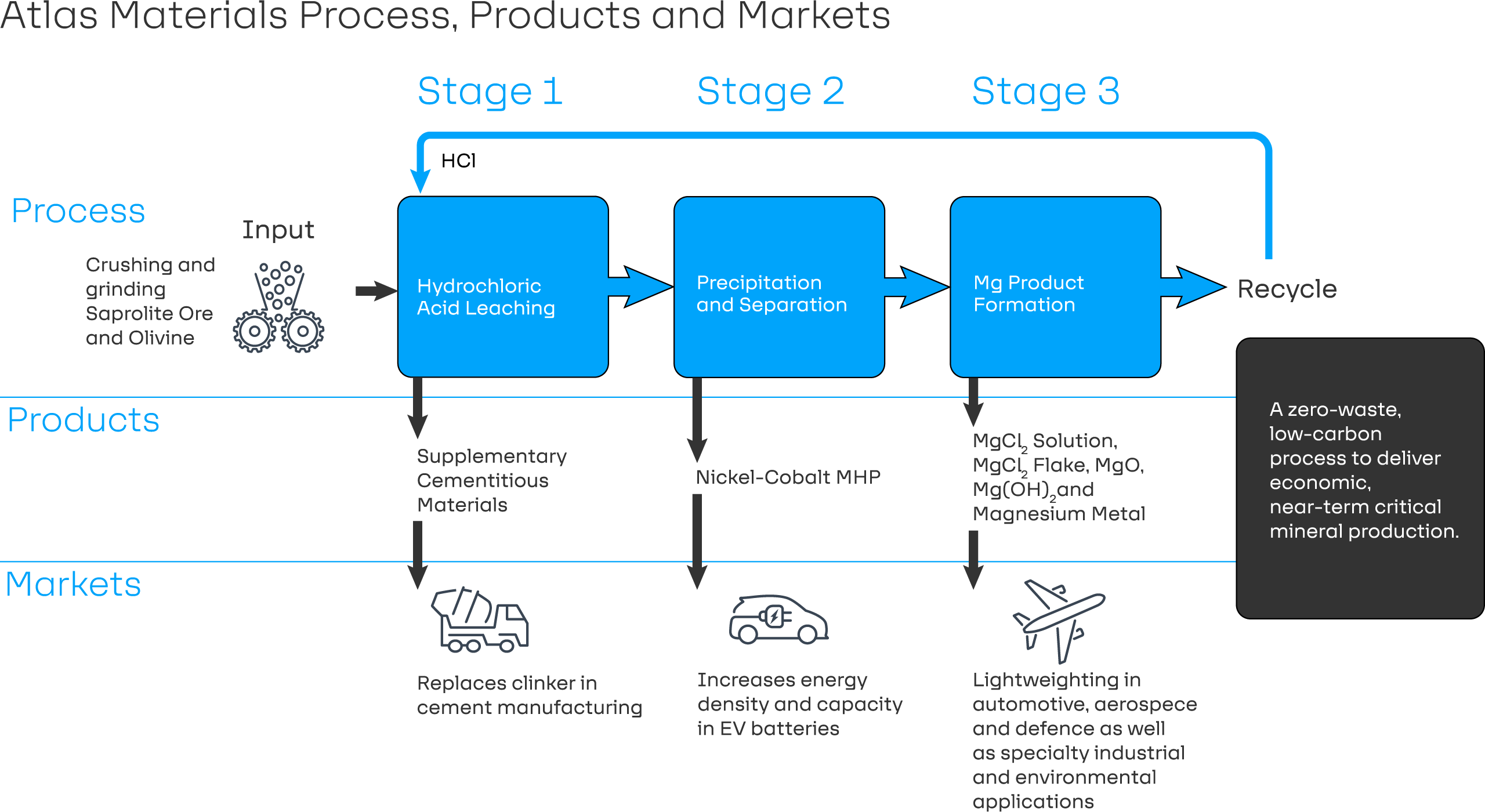

The Atlas Process uses acid and alkali reagents to process saprolite ore and produce zero-waste Magnesium Metal, a material used principally by the automotive and aerospace industries. The Atlas Process produces high purity Magnesium Chloride solution as an intermediary to the metal, and this solution can also be used in the production of Magnesium Oxide (applications include fireproofing, insulators, fertilizers, water treatment, plasma display screens) and Magnesium Hydroxide (applications include pharmaceuticals, plastics, construction materials).

Other marketable byproducts include Nickel and Cobalt MHP, used in battery applications, and a material that can be used as a Supplementary Cementitious Material (SCM) to enhance performance and reduce the carbon footprint of concrete production.

Works at atmospheric pressure

Works at atmospheric temperature

Combines existing proven processing technologies

Is proven on ores from many of the world’s major Nickel mines

Environmental Benefits

The breakthrough Atlas Process creates Magnesium Metal with no waste and low levels of CO2

Contributing to decarbonization

The Atlas Process uses significantly less energy than competing technologies and can be powered with renewable electricity.

Atlas Process byproducts will significantly abate emissions from heavily polluting industries – when powered by renewables:

- Our SCM product will have a significantly lower carbon footprint than standard clinker used in cement manufacturing.

- Our Magnesium Hydroxide will have lower product carbon intensity than traditional processes with an emissions intensity of only 0.17 tons of CO2 per ton of magnesium hydroxide.

Atlas’s Magnesium oxide/hydroxide products open the possibility of large-scale application to OAE – an emerging approach to micro-pH adjustment of ocean surface waters to accelerate the large-scale absorption of CO2 from the atmosphere.